Welcome to the Boeing Everett Factory, the colossal home of jumbo jets. With over 4.3 million square feet of space, this manufacturing facility in Everett, Washington is a testament to the engineering marvels of Boeing. Here, the world’s largest building by volume is a hive of activity, where skilled workers craft and assemble the iconic airplanes that take to the skies.

This facility, which started operations in 1967, has witnessed the birth of some of the most famous aircraft in history, including the legendary Boeing 747. Today, it continues to be at the forefront of aerospace innovation, housing advanced production systems and cutting-edge technology. Stepping inside the Boeing Everett Factory is a sensory overload. The sheer scale of the facility is awe-inspiring, with rows of giant wings, engines, and fuselages stretching as far as the eye can see.

And it’s not just the size that’s impressive – the precision and attention to detail that every worker puts into their craft is truly remarkable. Whether you’re an aviation enthusiast or simply curious about the incredible machinery that powers modern air travel, a visit to the Boeing Everett Factory is an experience like no other. Get ready to be amazed by the sights, sounds, and secrets of this monumental hub of aviation excellence.

Contents

- 1 History of the Boeing Everett Factory

- 2 Key Features and Specifications

- 3 Inside the Boeing Everett Factory – A Virtual Tour

- 4 Manufacturing Process of Jumbo Jets

- 5 The Economic Impact

- 6 Interesting Facts about the Boeing Everett Factory

- 7 Sustainability Initiatives at the Boeing Everett Factory

- 8 Conclusion: The Legacy of the Boeing Everett Factory

- 9 Author

History of the Boeing Everett Factory

The story of the Boeing Everett Factory begins in the early 1960s, when Boeing was looking to expand its production capabilities to meet the growing demand for commercial aircraft. The company had outgrown its existing facilities in the Seattle area, and the search was on for a new, larger site to house its operations.

After considering several locations, Boeing settled on Everett, a city north of Seattle, as the ideal location for its new factory. The site offered ample space, a skilled workforce, and proximity to the company’s existing infrastructure. Construction on the massive facility began in 1966, and just a year later, the first Boeing 747 jumbo jet rolled out of the newly completed factory.

The early years of the Everett factory were a whirlwind of activity, as Boeing raced to meet the overwhelming demand for the 747. The facility was expanded multiple times to accommodate the growing production needs, and soon it became the largest building in the world by gengtoto volume. Over the decades, the factory has continued to evolve, playing a crucial role in the development and manufacturing of other iconic Boeing models, including the 767, 777, and 787 Dreamliner.

Key Features and Specifications

Just the enormous scale of the Boeing Everett Factory is simply overwhelming. With more than 98 acres of space, the massive facility boasts over 4.3 million square feet inside; it’s actually the largest building by volume in the world provided you can fill that amazing amount of room with something–so why not cars? For reference, the factory floor would easily fit 911 basketball courts or 75 Boeing (Badassisest cartons are in a line)747s under its roof.

But the enormity of factory is not just for impact — indicative as it might be to people such as us, who do all this in miniature. The facility comprises separate specialized production zones devoted to different parts of the aircraft manufacturing process, from wing assembly all the way through final paint and delivery.

Inside the Boeing Everett Factory – A Virtual Tour

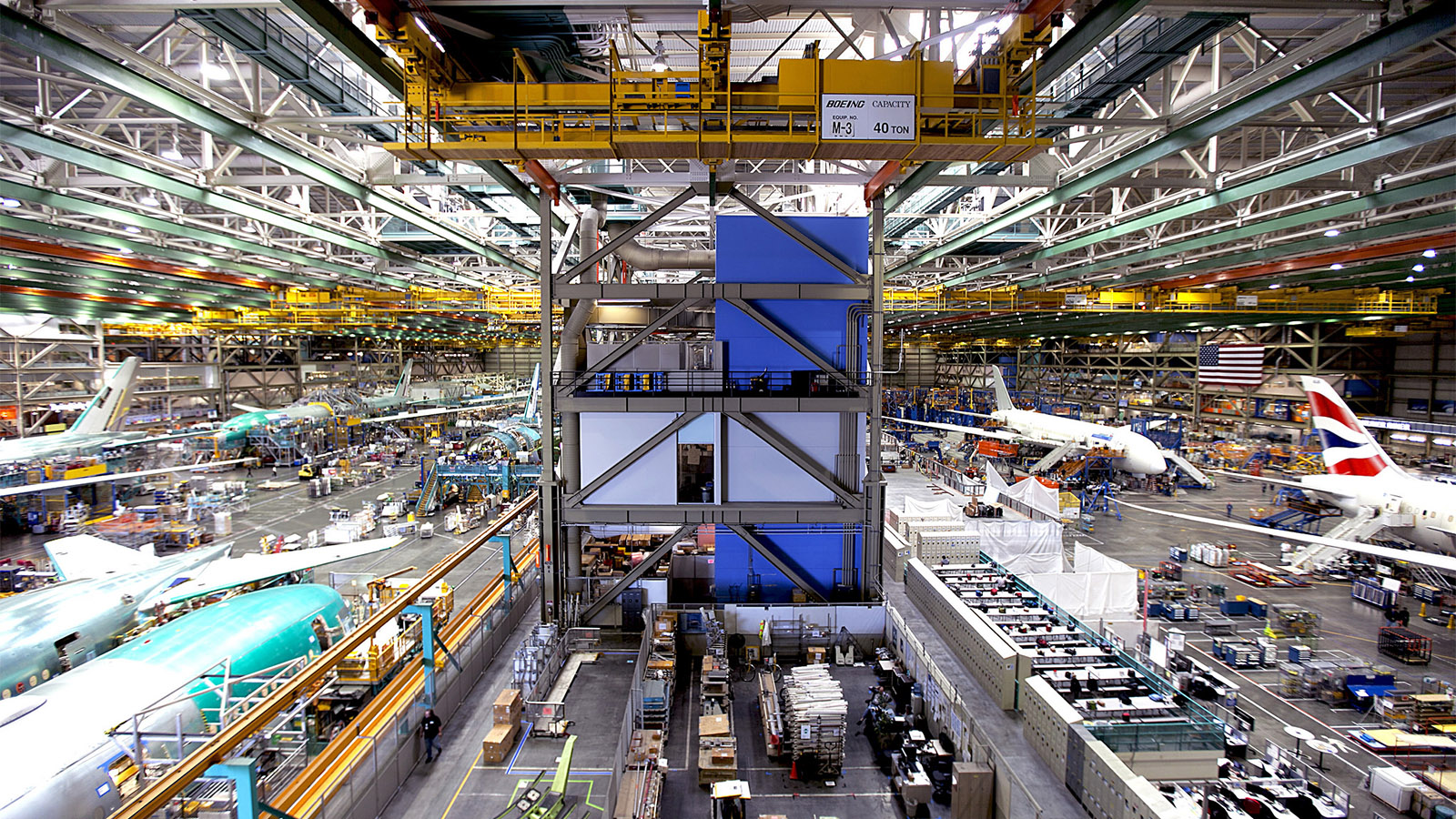

Walking into the Boeing Everett Factory is a truly awesome experience. This is a genuinely huge facility which becomes apparent instantaneously, with the large open spaces and high ceilings giving it an air of grand scale. As you pass through the various production areas, a completely linear view of manufacturing is revealed to your senses.

Of course, the first thing you will see is an impressive line of aircraft parts at different stages of preparation. Massive fuselages, wings and empennage (the tail assembly) stretch as far back into the distance as your eye can see each meticulously One waiting to be assembled together end product. The level of detail is amazing–each rivet, panel and system aligned just-so into place.

The further into the factory you go, a grander scale of the operation emerges. Overhead cranes with massive lifting capabilities glide around overhead picking up and placing heavy aircraft parts down to the millimeter. There is so much noise of power tools and riveting guns, mixed with the sound silence produced by other industrial activities. Blue-suited brackies perform at speed, with a sense of intent and focus in the construction of these magnificent machines.

Manufacturing Process of Jumbo Jets

Story by Ian Phillips Photos by David Bailey | The manufacture of jumbo jets at the Boeing plant in Everett is a meticulously choreographed pas de deux of precision engineering and skilled artisans. Every step from the first arrival of raw material to final assembly and delivery is audited with precision.

This is where the journey starts, as all types are delivered to JAS’ factory and join already completed fuselages, wings or empennage. Each one of these parts is thoroughly vetted and prepared for assembly, with modifications or fixes if needed before they are ready to go into the final product.

Following the preparation of all sources, assembly may start This is where the actual magic starts to take place in Everett as their highly experienced workforce and top-tier production system begin fitting all of the pieces together. Integration of the fuselage is a milestone as it represents the joining for first time in following specific order, riveting and bonding along with few unique technique to form one-piece-manufacture each section.

The Economic Impact

The Boeing Everett Factory is not just a marvel of engineering and manufacturing – it is also a vital economic engine for the local and regional economy. As one of the largest employers in the state of Washington, the factory plays a crucial role in supporting thousands of jobs and generating billions of dollars in economic activity.

According to the latest data, the Boeing Everett Factory employs over 30,000 workers, making it one of the largest industrial facilities in the United States. These skilled workers, ranging from engineers and technicians to assembly line workers and support staff, earn competitive wages and enjoy a range of benefits that contribute to the economic well-being of the surrounding communities.

But the economic impact of the Everett factory extends far beyond its direct employment. The facility is part of a vast supply chain that includes hundreds of suppliers and vendors, all of whom rely on the factory’s orders and contracts to sustain their own businesses. This ripple effect generates additional jobs and economic activity throughout the region, further bolstering the local economy.

Interesting Facts about the Boeing Everett Factory

The Boeing Everett Factory is a veritable treasure trove of fascinating facts and figures. Here are just a few of the most interesting tidbits about this colossal industrial marvel:

- The factory is so large that it has its own zip code: 98208.

- The facility’s roof is so massive that it could cover 75 Boeing 747 jumbo jets.

- The factory’s internal roads are over 48 miles long, long enough to drive from Seattle to Everett.

- The factory’s electrical system is capable of powering a city of 100,000 people.

- The facility’s fire suppression system includes over 100 miles of piping and can deliver up to 4,000 gallons of water per minute.

- The factory’s workforce is so large that it has its own onsite medical clinic, fire department, and security force.

- The factory’s cafeteria can serve up to 10,000 meals per day to the hungry workers.

- The factory has its own railway system, with over 27 miles of track, to transport heavy equipment and materials.

Sustainability Initiatives at the Boeing Everett Factory

As one of the world’s leading aerospace manufacturers, Boeing has a responsibility to ensure that its operations are as environmentally sustainable as possible. The Everett factory, being the company’s largest and most prominent production facility, has been at the forefront of these sustainability efforts.

One of the most significant initiatives at the Everett factory is the implementation of a comprehensive waste reduction and recycling program. The facility has set ambitious goals to divert as much waste as possible from landfills, with a focus on recycling and repurposing a wide range of materials, from scrap metal and composites to office supplies and packaging.

The factory has also made significant investments in energy efficiency, with the installation of advanced HVAC systems, LED lighting, and other technologies designed to reduce the facility’s carbon footprint. Additionally, the company has explored the use of renewable energy sources, such as solar power, to further minimize the environmental impact of its operations.

Conclusion: The Legacy of the Boeing Everett Factory

The Boeing Everett Factory stands as a testament to the ingenuity, dedication, and sheer determination of the countless individuals who have contributed to its success over the past five decades. From the visionary engineers who conceived of this colossal facility to the skilled workers who bring it to life every day, the Everett factory has become a symbol of American manufacturing excellence.

As the world’s largest building by volume, the Everett factory has not only produced some of the most iconic and influential aircraft in history but has also served as a hub of innovation and technological advancement. If you like reading this article then please consider reading our article about CFA.